This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

About This Project

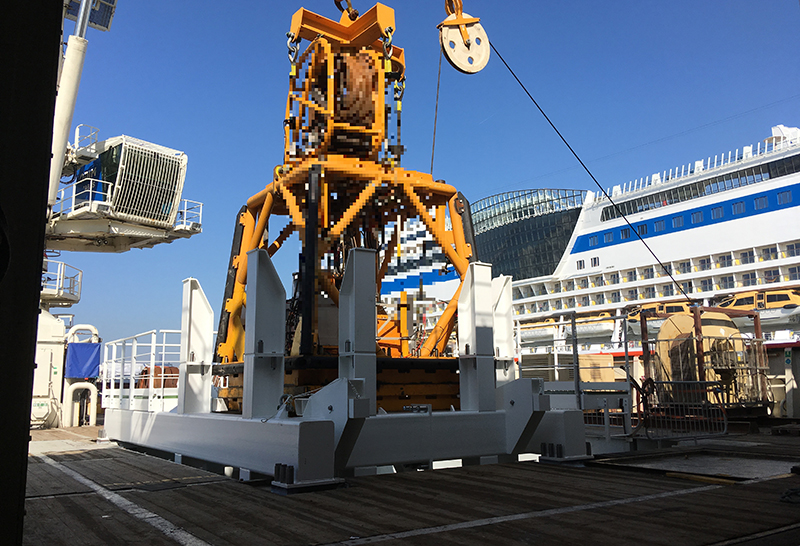

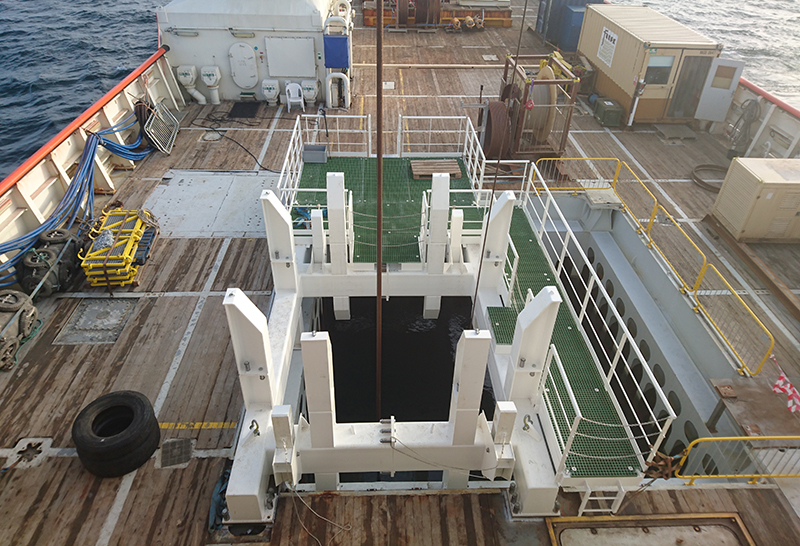

Fabrication, delivery and installation of a moonpool reducer structure.

Moonpool reducer structure

Fabrication, delivery and installation of a moonpool reducer structure. Moonpool dimensions of the client vessel were to be reduced in order to properly operate project specific equipment, the current dimensions of the moonpool allowed the unit to move too much. A cover frame on top of the existing moonpool was developed by our sister company Saltwater Engineering to reduce this excessive movement. Additional specifications such as working platforms (1000kg/m 2 ), railings, stairs, ladders, sheave blocks and a store function of project equipment were designed, manufactured, coated, delivered, assembled and installed on site.

On site installation was achieved by means of bolted connections assuring placement on sister vessels in due time.

Challenges and solutions

Main challenge was the timeframe and availability of materials in which this frame needed to be made. Only fourteen (14) days were available from first offer to final delivery of the frame. Complete delivery of the full scope of work (including documentation package) was achieved by our local partners, short lines between the engineering and subsequent production proved again to be of great benefit as this resulted in the shortest lead time possible.

Project

Main dimensions and weight

- Assembled height: 5.00m

- Foot print: 9.50 x 4.50m

- SWL sheave arm: 1.4tons

- Weight: approx 12500kg

Production methods and delivery

MIG/MAG Welding

100% Magnetic Particle Inspection of the welds

Delivery- and installation on site to client requirements

Load testing of all padeyes